PIM & SPAPI Setup

During my time at Rev Supply Co., it was the third largest retailer of automotive fasteners on Amazon. While much of my energy went into outsmarting the competition, I noticed very quickly that the company’s biggest challenges didn’t come from competitors, but from operational roadblocks. Many such roadblocks existed on Amazon, the marketplace making up the lion’s share of Rev Supply’s business. I removed these and other roadblocks by combining Product Information Management (PIM) software with outside-the-box thinking.

Note that any statements made here regarding Amazon’s practices are personal inferences. I don’t have insider knowledge about Amazon’s content approval systems or staff.

Amazon Content Changes: A Common Struggle

Speaking from personal experience and plenty of anecdotes, I say it as a matter of fact that updating content on Amazon is a rocky road. Mega corporations partner with Amazon directly, appointing people on both sides to syndicate content. I’m sure those arrangements run smoothly. Everyone else, on the other hand, has to deal with a broken approval process and make do with clunky tools.

Humans In The Loop

To protect itself from liability over explicit material, Amazon uses a content approval process that combines algorithms with human reviewers. The algorithms seem to flag content based on easily detectable factors. If nothing is flagged, the content is passed to a human reviewer for approval or rejection. These reviewers are likely underpaid, pressured by rigid KPIs, and face consequences for approving content that violates policy — but no consequences for rejecting content that complies. That creates a system where disapprovals become the path of least resistance, leading to routine, baseless rejections.

These reviewers are likely underpaid, pressured by rigid KPIs, and face consequences for approving content that violates policy — but no consequences for rejecting content that complies. That creates a system where disapprovals become the path of least resistance, leading to routine, baseless rejections.

Brand Trust Complications

In the automotive parts market, returns are unusually common. This is not always due to product quality, but rather because part fitment is complex and many customers ignore details before buying. A high return rate can indirectly hurt brand trust on Amazon, as frequent returns seem to bias the platform’s approval process against your listings.

Limited Feedback and Frontend Ambiguity

Whether you’re on Seller Central or Vendor Central, Amazon’s content management tools rarely notify vendors when uploads are rejected. Even the few that offer feedback, such as the bulk image uploader, lack detail. When reasons are provided, they are often inaccurate. Adding to the frustration, what you see in the backend can be entirely different from what customers see on the frontend. Your edits may appear accepted internally yet never go live, and the only way to catch this is by manually comparing pages. Fixing these mismatches requires filing a complaint case, which is a slow and tedious process.

The Ad Hoc Approach: A Common Business Myopia

Even if Amazon’s backend worked flawlessly, it would still require heavy manual input due to interfaces built for editing one item at a time. Some modules, like the image manager, are marginally faster than the listing editor, but they’re still inefficient. So, not only does effort fail to scale effectively within Amazon, it also cannot scale beyond Amazon, making such effort a poor investment of paid time.

Sometime before I joined Rev Supply Co., a decision was made to manage text content in spreadsheets, which could be uploaded using Amazon’s New Item Setup (NIS) templates. But while spreadsheets may entertain the concept of a single source of truth (SSOT), they have very limited scope, especially when you consider how many data transformations are needed to publish on multiple platforms. Besides, uploading new spreadsheets still takes time, particularly on Amazon, where NIS schema don’t allow partial entries.

Adopting Product Information Management (PIM) Software

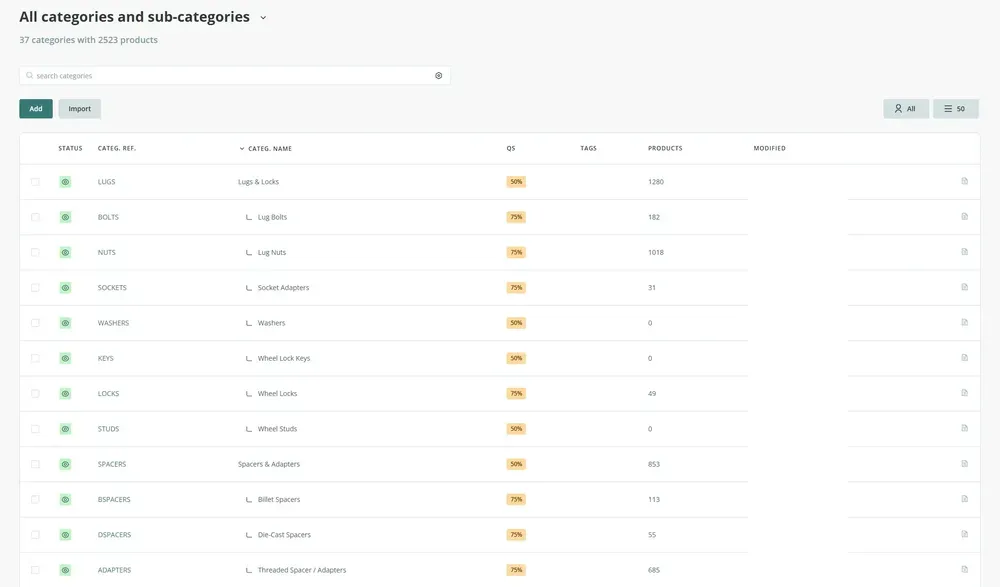

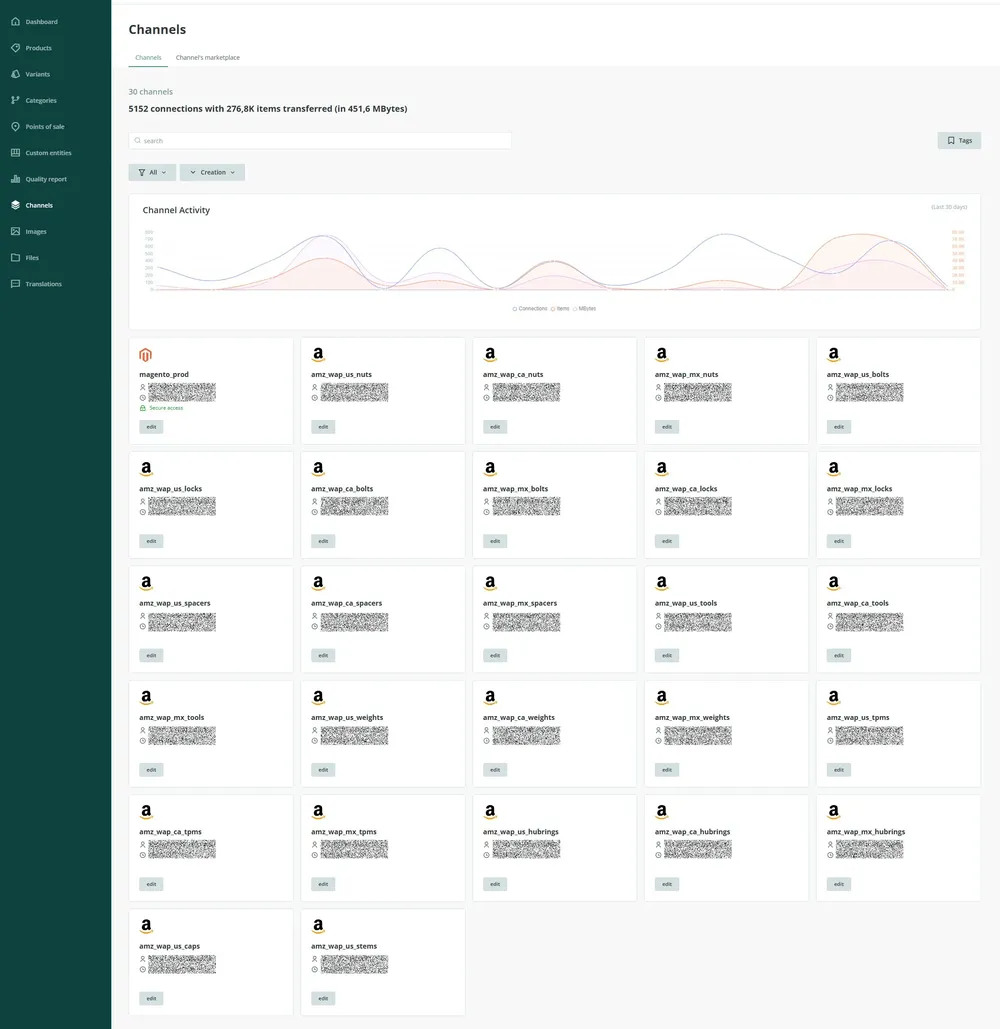

PIM softwares are considered a best practice because they allow product content to be managed from a single source and propagated to multiple channels, removing the high manpower cost and error-prone nature of managing multiple channels separately. For these reasons, I made integrating Sales Layer a top priority at Rev Supply Co. from day one.

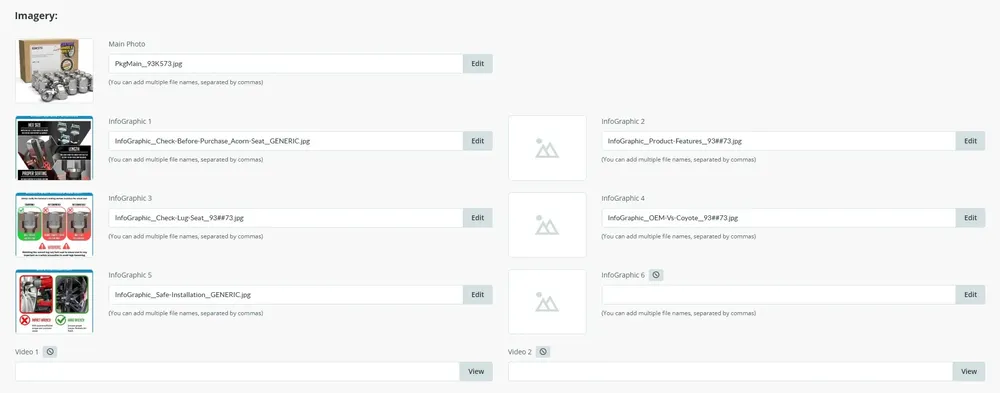

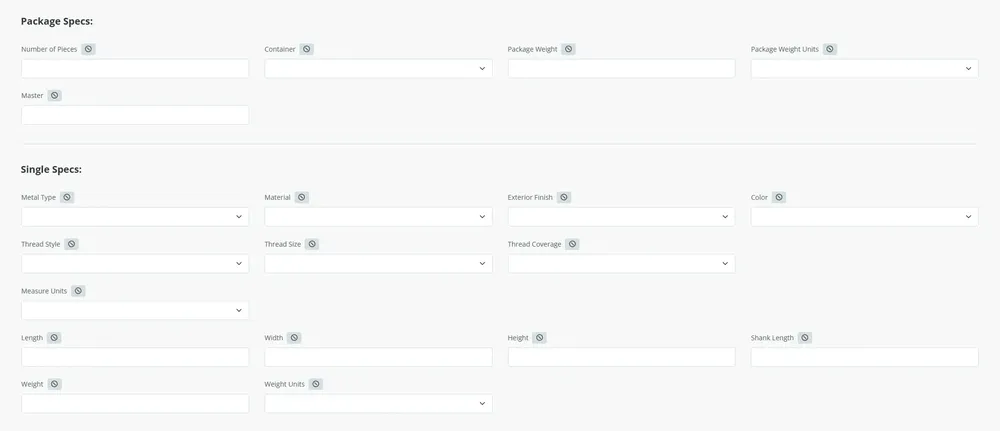

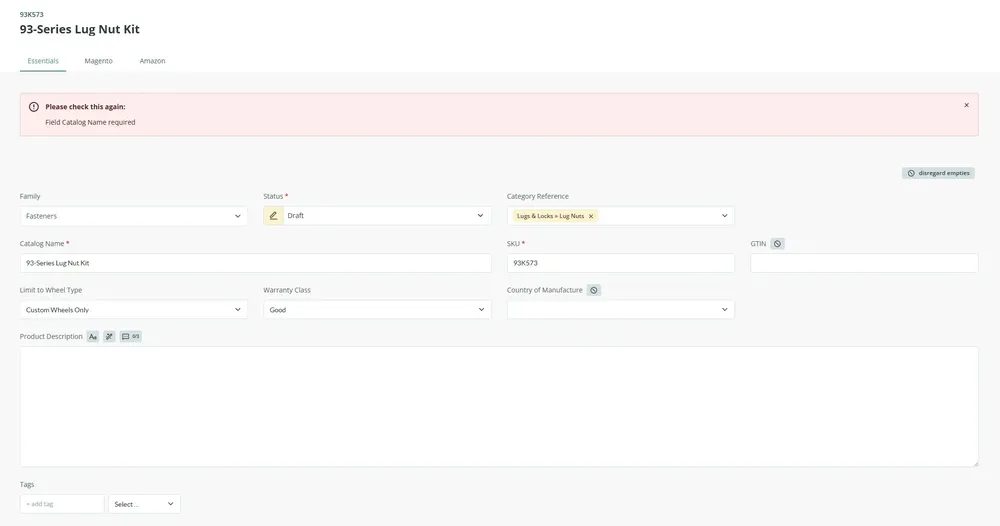

My implementation was highly tailored for Rev Supply Co.’s use case. Everything that could be was standardized. For example, I set up several product families, and each family utilized a unique layout catering specifically to that type of item. Fields used data validation whenever possible, which reduced human error, ensured formatting consistency, and sped up data entry.

Managing images is also naturally easier with a PIM, but in this case, the digital asset management strategy I developed in //Opheim removed the need completely. Even when adding a whole new product to the catalog, accurate, up-to-date images were already present in the proper fields because of the tight naming conventions and procedural automations I instituted for my creative staff.

With Sales Layer, we even gained the ability to localize our content for different global markets and manage translations intuitively. While Spanish translations generated by the AI weren’t always perfect, they reduced effort dramatically, and any mishaps were easily corrected by our Argentine listing managers.

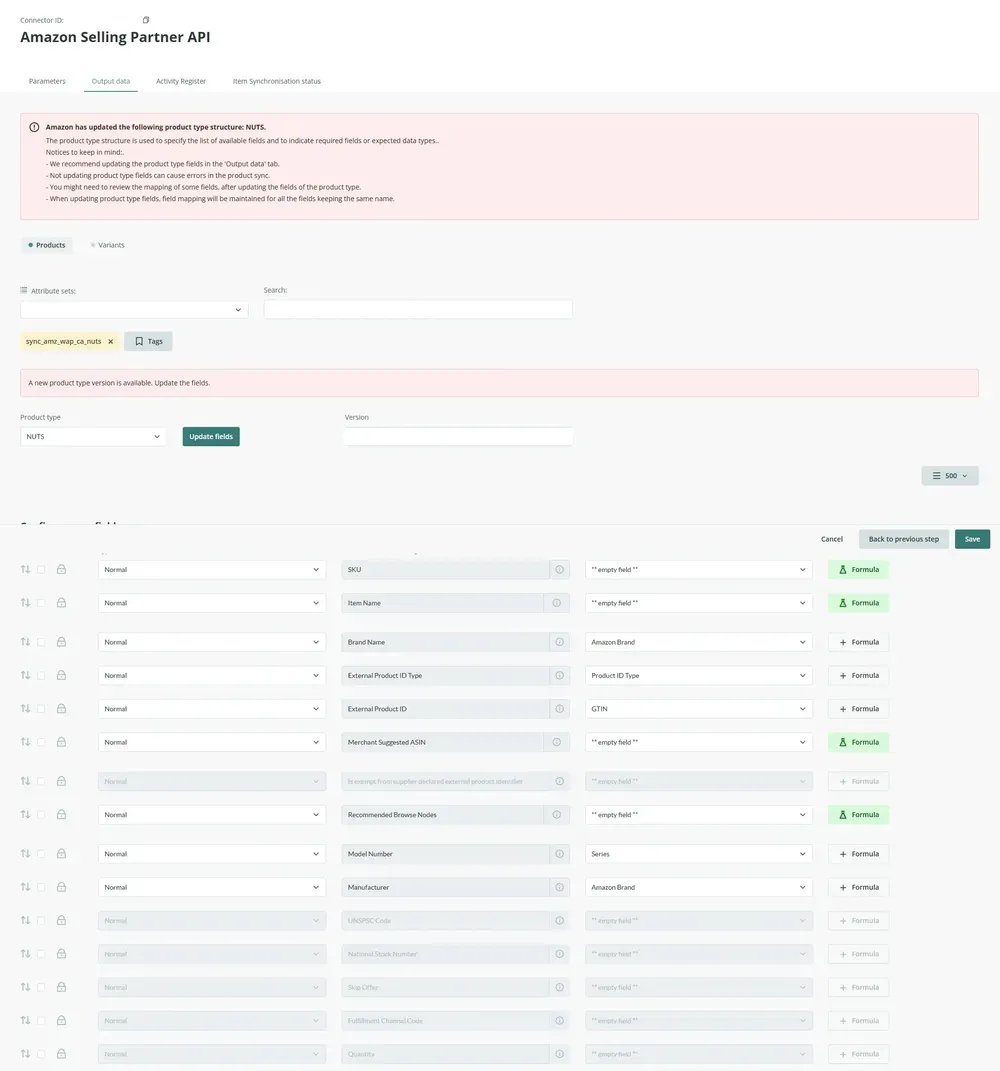

Of course, the pièce de résistance was the PIM’s connection to multiple marketplace APIs, all of which I configured personally. These included connectors for our own Magento sites, eBay, AliExpress, and Amazon’s marketplaces in the US, Canada, and Mexico. Within each connector were custom SQL formulas transforming text to be suitable for the platform. As soon as these connectors were complete, my team no longer had to maintain content in more than one place, and the impact on data quality was instantly noticeable.

The PIM alone couldn’t overcome content rejection challenges on Amazon, however, since content submitted over API is subject to the same checks as content submitted through Seller Central. To break through this barrier, I had to augment Sales Layer’s SPAPI connections with what you might call brutal ingenuity.

Image Re-Hash Script

As I mentioned before, Amazon’s content approval process seems to have two parts: the algorithm and the human reviewers. Based on what I’ve seen, the algorithm seems capable of identifying obvious violations, such as badges set over a MAIN photo or unauthorized use of registered intellectual property (think car manufacturer logos). Our images were always compliant, and although that often didn’t matter to Amazon personnel, I knew continuous re-submission (which I’ll explain next) would be a sound strategy. The thing is, Amazon’s algorithm can detect when the same image is submitted twice. When a duplicate image is detected, it never gets to the human reviewer, it gets ignored.

To remedy this, I wrote a simple image processing script that uses NConvert to apply gaussian noise to every image. The noise is visibly imperceptible, but since it adds randomness to the file’s hash, Amazon’s duplicate detector has no idea it’s looking at an image it has seen before.

Scheduling my script to reprocess all of the images in our repository on a daily basis, I also set up a nightly pull in Sales Layer to replace the old images with new ones.

Forcing Repeated API Pushes

With product data now being held to a high level of accuracy and newly hashed images loading to Sales Layer’s database daily, the last step was to force Sales Layer’s SPAPI connectors to push to Amazon continuously. Not just when a product is updated, and not just the updated product. All products, repeatedly. Again. And again. And again. And again. Over and over. Basically, this is like waging a war of attrition with Amazon’s systemic oversights. If you’re sending 100 submissions in a week, 99 may be rejected, but one will be accepted. And one is all you need.

The Outcome

Days would still pass before we could see changes reflected on Amazon’s frontend, but ultimately, the changes did go up. Every time. And it was all happening automatically now, without an employee bickering with Amazon support reps, staring at their browser all day, and drowning in job tedium.

Within 60 days of implementing this system, manual listing edits on Amazon dropped by over 90%, freeing roughly 80 staff hours per week for higher-value marketing work. Approval rates for image and text updates rose from an estimated 10–15% to 88.7%, and cross-channel catalog accuracy improved to 94.7% based on internal audits. The streamlined workflow also enabled us to synchronize more than 4,500 SKUs across six different sales channels in 24 hours — a process that used to take weeks.

Relying on this foundation, I was able to scale marketing operations effectively, not just on Amazon, but across the web.